There are many unique tools used in our nursery operations – these are a few of our tools of the trade.

Operational Pollen Gun

This device uses compressed nitrogen to inject pollen into a pollination bag. Flower pollination in loblolly pine takes place during the spring, and Mother Nature allows only for a very small window to complete this task. Typically, the female flowers are receptive only for about two weeks with the peak lasting only a few days in some cases. Larger operations will sometimes pollinate up to 40,000 bags during this two-week period.

This device uses compressed nitrogen to inject pollen into a pollination bag. Flower pollination in loblolly pine takes place during the spring, and Mother Nature allows only for a very small window to complete this task. Typically, the female flowers are receptive only for about two weeks with the peak lasting only a few days in some cases. Larger operations will sometimes pollinate up to 40,000 bags during this two-week period.

Pollination Tube

Determining flower receptivity is very important in loblolly pine tree breeding. This casing material is wrapped around the female flowers to prevent contamination from foreign pollen. By looking through the plastic, a breeding expert can tell the exact time when pollination should occur. This type of pollination tool is more difficult to work with and takes longer to install, therefore it is rarely used operationally. However, it is still used some for research and for pollen collection.

Pollination Bag

This bag is used to isolate female flowers during the spring when pollination occurs. The bags are typically installed well in advance of pollen flight. Proper timing is critical; if the bags are installed too soon, it can affect development of the flowers. These bags are installed around each group of flowers; the process is very labor intensive. The bags are secured by using zip ties that are tightened around the base of the bag. The type commonly used has a small flap with a plastic window allowing the tree breeding expert to view the flowers prior to controlled pollination.

This bag is used to isolate female flowers during the spring when pollination occurs. The bags are typically installed well in advance of pollen flight. Proper timing is critical; if the bags are installed too soon, it can affect development of the flowers. These bags are installed around each group of flowers; the process is very labor intensive. The bags are secured by using zip ties that are tightened around the base of the bag. The type commonly used has a small flap with a plastic window allowing the tree breeding expert to view the flowers prior to controlled pollination.

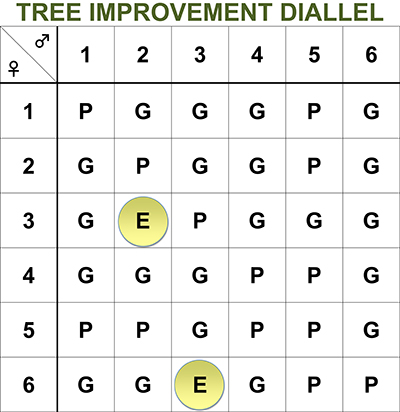

Tree Improvement Diallel

As with any type of breeding, different crosses yield different results. The chart provided shows six different loblolly pine clones that are crossed and result in either poor, good or excellent trees. This type of breeding was the foundation of our tree improvement program that began about 50 years ago, and these crosses resulted in our first-cycle loblolly pine orchard. The seedlings that we are producing now come from a third-generation orchard, and, within the next two years, we plan to start grafting our fourth-generation orchard at our New Kent Forestry Center.

As with any type of breeding, different crosses yield different results. The chart provided shows six different loblolly pine clones that are crossed and result in either poor, good or excellent trees. This type of breeding was the foundation of our tree improvement program that began about 50 years ago, and these crosses resulted in our first-cycle loblolly pine orchard. The seedlings that we are producing now come from a third-generation orchard, and, within the next two years, we plan to start grafting our fourth-generation orchard at our New Kent Forestry Center.

Loblolly Pine Pollen

If you live in eastern Virginia, I’m sure you are familiar with the “pollen cloud” that floats through our neighborhoods every spring. That cloud marks the beginning of loblolly pine tree breeding in Virginia. This pollen must be collected from mature trees prior to the pollen flight. Catkins are collected each spring by breeding experts and placed in a controlled temperature environment where the pollen is dried and shed from the catkins. After this natural process, the pollen is then delicately poured into plastic bottles and refrigerated to be used later in the season.

Control Pollination Tags

After breeding takes place, proper tagging must be done so that personnel collecting cones later in the season know which cones are control pollinated. The tags are installed on the branch just below the pollinated flowers. Since it takes 18 months for the cones to mature, we can potentially have two different controlled crossed on the same branch at the same time. Therefore, proper identification is paramount during this operation.

Banding Cone

This cone attached to a metal pipe is used to bundle groups of 50 seedlings as they are transported down a conveyor belt during our packaging operation. Like most nursery equipment, this device was hand made by local machine shops near the nurseries. On a typical day, one banding person will handle up to 300,000 seedlings. It often takes two people banding to keep up with the daily production goals.

This cone attached to a metal pipe is used to bundle groups of 50 seedlings as they are transported down a conveyor belt during our packaging operation. Like most nursery equipment, this device was hand made by local machine shops near the nurseries. On a typical day, one banding person will handle up to 300,000 seedlings. It often takes two people banding to keep up with the daily production goals.

Canvas Seedling Wrapper

These hand-sewn wrappers are used for transporting seedlings from the field to the cold storage units. Since most of the VDOF seedlings are grown bareroot, we must protect the roots from being dried out during transportation. These canvas wrappers not only protect from the sun and wind but also are waterproof to allow for seedlings to be watered down while awaiting to be packaged. A typical time frame between lifting and packaging is one to two days.

Seedling Inventory Tools

These handmade tools are used for measuring seedlings within a seedbed. In most bare-root operations, the number of seedlings grown is typically at a level where 100% inventories are not cost effective. Therefore, temporary plots are established and measured to determine inventory levels. With this approach, there is always a “standard of error” that must be accounted for. That often is why inventories can fluctuate throughout the year and seedlings become available later in the season. The actual number is often greater than the estimated number.

Vinyl Seedling Bag

Bag used to carry bare-root seedlings across a site during planting. The bag protects the seedlings from drying out during the planting operation. Today, planters use much larger double bags made from heavy-duty vinyl, as opposed to the older canvas bags that were used in past years.

Canvas Seedling Bag

Bag used to carry bare-root seedlings across a site during planting. The bag protects the seedlings from drying out during the planting operation. Today, planters use much larger double bags made from heavy-duty vinyl.

Hoedad

Planting bar used for planting bare-root seedlings. The hoedad is swung one-handed overhead to penetrate the soil to create a slit. After inserting the seedling into the slit, the hoedad is pushed back into the ground to press a wedge of soil against the seedling.

Planting bar used for planting bare-root seedlings. The hoedad is swung one-handed overhead to penetrate the soil to create a slit. After inserting the seedling into the slit, the hoedad is pushed back into the ground to press a wedge of soil against the seedling.

Dibble Bar

Wedge-shaped bar used for planting bare-root seedlings. The dibble is pushed into the ground with the aid of the footstep; then the blade is moved back and forth to create a slit. After inserting a seedling into the slit, the dibble is pushed back into the ground to press a wedge of soil against the seedling.

Wedge-shaped bar used for planting bare-root seedlings. The dibble is pushed into the ground with the aid of the footstep; then the blade is moved back and forth to create a slit. After inserting a seedling into the slit, the dibble is pushed back into the ground to press a wedge of soil against the seedling.

Mechanical Pine Seedling Lifter

In the early years of the Virginia Department of Forestry’s nursery operations, seedling harvesting was performed by hand, which required a large number of people and was very inefficient. In 1968, the department borrowed a prototype mechanical seedling lifter from New York. After experimenting with the prototype, the department’s employees designed and built a machine using rear ends out of trucks and many custom-made parts. The employees developed the country’s first full-bed mechanical pine seedling lifter, which was capable of harvesting more than 20 million seedlings each season. The technology was shared with anyone who was interested, and today’s seedling harvesters are based upon this design.

In the early years of the Virginia Department of Forestry’s nursery operations, seedling harvesting was performed by hand, which required a large number of people and was very inefficient. In 1968, the department borrowed a prototype mechanical seedling lifter from New York. After experimenting with the prototype, the department’s employees designed and built a machine using rear ends out of trucks and many custom-made parts. The employees developed the country’s first full-bed mechanical pine seedling lifter, which was capable of harvesting more than 20 million seedlings each season. The technology was shared with anyone who was interested, and today’s seedling harvesters are based upon this design.

Additional Resources

[posts_table columns="image,tax:Audience,title,cf:id_number:ID,content:Description,tax:Media,button" post_type="document-library" rows_per_page="5" exclude_term="Audiences:no, Media:news-releases" term="document-category:nurseries" filters="tax:document-category:Select Category,tax:document-tags:Select Tag,tax:Media:Select Content Type"]Contact Us

For more information or questions, e-mail us or use our contact form.